Speed range and precision

Wider speed ranges and more precise digital controls increase cost. Models offering 10-500 RPM with 1 RPM resolution cost more than basic 50-250 RPM units. Consider whether your protocols actually require extreme speeds or if standard ranges suffice.

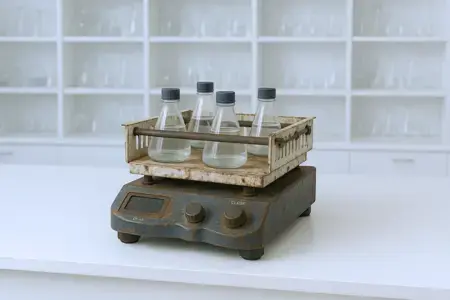

Platform size and weight capacity

Larger platforms and higher weight capacities require stronger motors and more robust construction. A unit handling 7.5 kg costs more than a 2 kg model, but buying excess capacity you won't use wastes budget.

Incubator compatibility

CO2 incubator models require special materials and compact designs that resist corrosion in high-humidity environments. These features add cost but are essential for cell culture applications. Room-temperature models cost less if you don't need incubator operation.

Control systems and displays

Digital displays, microprocessor controls, and programming capabilities increase price compared to analog controls. While digital provides better precision and documentation, simple analog controls work fine for basic mixing needs.

Construction materials

Stainless steel platforms, chemical-resistant housings, and sealed electronics cost more than basic materials but extend equipment life in harsh environments. Standard labs may not need premium materials designed for extreme conditions.

Brand premium and features

Established brands charge more for reputation and include features like smartphone apps or proprietary software. These additions significantly increase price without improving basic mixing performance.

Warranty and support

Longer warranties and comprehensive support programs add to initial cost but may provide value through reduced downtime. Balance warranty cost against your ability to handle basic maintenance internally.