Motor power and durability

Basic 150-watt motors cost less but may struggle with tough tissues. Heavy-duty 500+ watt motors handle anything but add $500-1000. Consider your actual sample types - not every lab needs maximum power.

Number of probe sizes included

Single probe packages are cheapest, but you'll likely need 2-3 sizes eventually. Kits with multiple probes cost more initially but provide better value than buying probes separately at $200-400 each.

Control system complexity

Analog speed controls keep costs down. Digital displays add 20-30% but provide reproducibility. Data logging and programmable methods add another 30-50% - valuable for regulated environments, unnecessary for research.

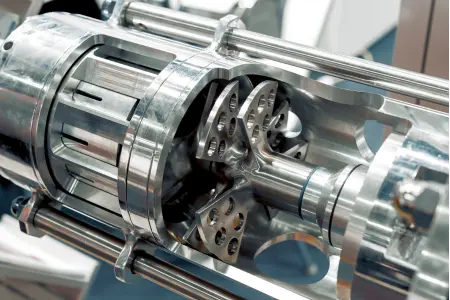

Construction quality

Sealed bearings, chemical-resistant housing, and robust internal components add cost but extend lifespan. Cheaper units may need replacement every 2-3 years, making quality construction more economical long-term.

Brand premium

Established brands charge 50-200% more for similar specifications. You're funding their marketing, not getting better homogenization. Practical brands deliver equivalent performance without the markup.

Service and warranty

Extended warranties and service contracts can add 10-20% annually. Consider whether you can handle basic maintenance internally versus paying for service plans you might not use.

Replacement parts availability

Systems using standard bearings and seals cost less to maintain than those requiring proprietary parts. Factor in long-term maintenance costs, not just purchase price.